Wide seam laser welding machine working principle

2025-02-19

Wide seam laser welding machine is an advanced welding equipment, its working principle is based on the deep integration of laser technology and material science. The following is a detailed explanation of its working principle:

First, the basis of laser technology

Laser welding technology mainly relies on high-power laser to produce a continuous laser beam, the laser beam through a series of optical components for transmission, focusing and control. In the wide seam laser welding machine, the laser emits a high energy density beam, which is the core of the entire welding process.

Second, wide seam laser welding machine working principle

1. laser generation: first of all, the high-power laser produces a continuous laser beam. 2. laser transmission and focusing: laser transmission and focusing: the laser beam is the core of the whole welding process.

2. Laser transmission and focusing: the laser beam is transmitted to the welding head through the optical fibre, and then through the focusing lens to focus the beam to a very small spot, in order to form a high heat concentration area on the workpiece.

3. Weld formation: When the laser beam strikes the surface of the workpiece, the material is rapidly heated to the melting point and a molten pool is formed. As the laser beam moves, the molten pool moves along a set path to form the weld.

4. Material connection: Under the continuous action of the laser beam, the two parts of the workpiece are connected by the molten pool.

III. Features and Advantages

Wide seam laser welding machine can handle a large range of weld seams, with the advantages of fast welding speed, small heat-affected zone and high welding quality. In addition, it can adapt to a variety of materials, including metals, alloys, etc., with a wide range of applications.

Fourth, the operation process

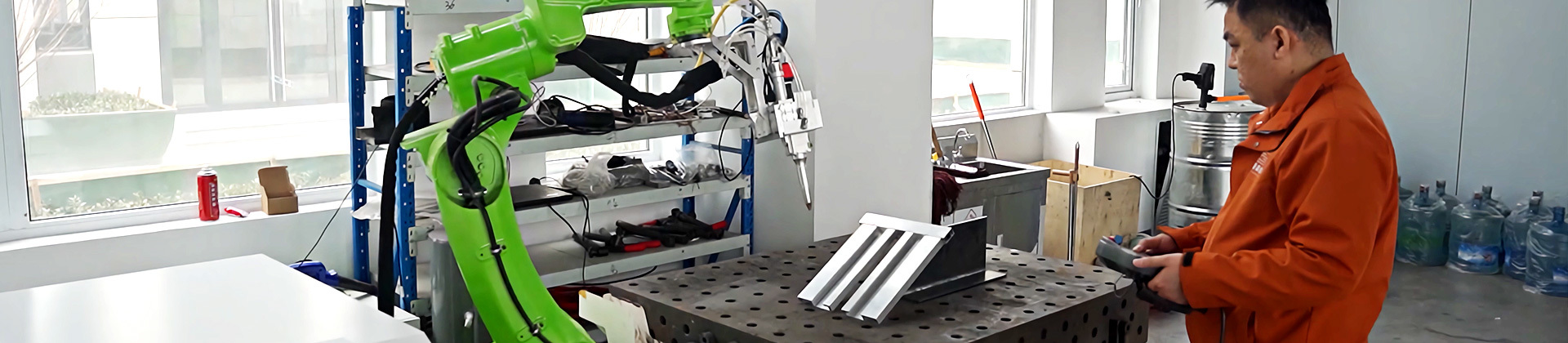

When operating the wide seam laser welding machine, you need to position the workpiece accurately first, and then set the laser parameters, such as power and speed. During the welding process, the operator needs to monitor the welding quality in real time to ensure the stability of the welding process.

V. Application Areas

Wide seam laser welding machine is widely used in automotive, aviation, shipping, electronics and other fields, especially in the need for high-precision, high-quality welding occasions are widely used.

Conclusion

The working principle of wide seam laser welding machine is based on the combination of laser technology and material science, which has high efficiency and high quality welding ability. With the continuous progress of technology, it will be more and more widely used in various fields. For manufacturing industries that require high precision and high quality welding, wide seam laser welding machine is an indispensable and important tool.

Previous page: