**Unveiling Kempson Laser's Breakthrough in 12mm Welding**

2025-10-13

[Introduction]

While peers were still struggling with splashing during the welding of 8mm steel plates, Kempson's laser welding gun had quietly penetrated 12mm steel plates - twice the industry average thickness. This is not only a digital leap, but also a revolution in thick plate welding technology. Of course, there is no magic here, only absolute control over every splash, every joule of heat, and every millimeter of precision.

Breaking through: Reshaping Welding Boundaries with 'Light'

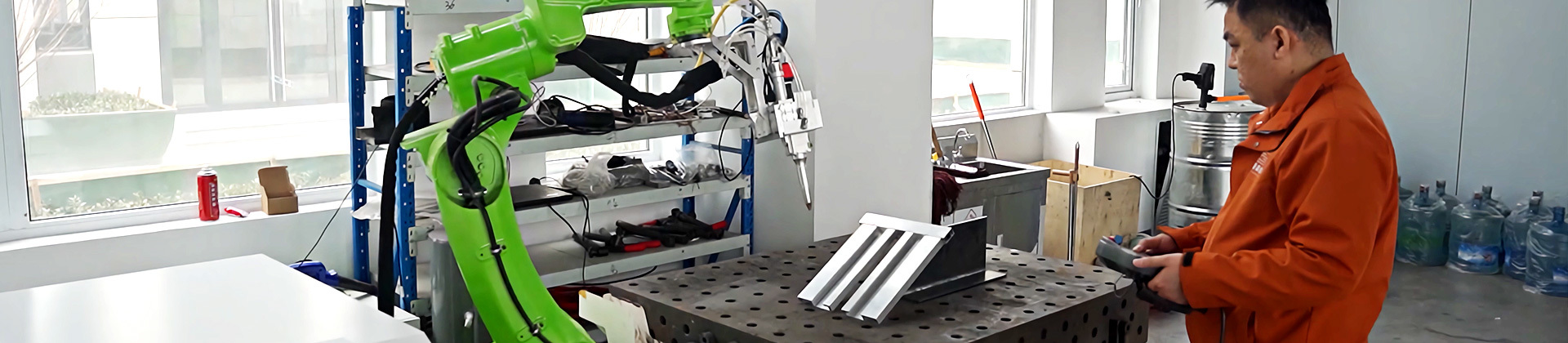

At Kempson Laboratory, the R&D director proudly pointed to a set of comparative samples and said, "The thickness limit of traditional welded steel plates is 6 millimeters, but we have been able to achieve 12 millimeters - thick plates can be penetrated in one go without the need for multiple layers of welding." What is even more gratifying is that Kempson uses zero splash closed-loop control method to increase the weld strength by 25%, directly eliminating the grinding process. This alone has saved customers a significant amount of manual polishing costs.

Kempson 6000W laser welding and product details

Kempson 6000W laser welding and product details

Innovation: Technical genes hidden in details

At Kempson, innovation is not only reflected in breakthroughs in welding thickness, but also in every detail.

Gas shortage alarm device: Although laser welding has high efficiency, the cost of use is also high, and frequent replacement of protective lenses is a pain point in the industry. The new welding gun developed by Kempson is equipped with a gas shortage alarm device. When the gas is used up, the welding gun will automatically stop emitting light, effectively protecting the protective mirror and avoiding damage due to insufficient gas, greatly reducing the cost of use.

Anti splash gun barrel/nozzle: Compared with ordinary copper nozzles, the new welded copper nozzle can block 60% of splashes from entering the graduated tube. There is also an anti splash device installed inside the scale tube, which further prevents 60% of splashes from entering the gun, effectively protecting the internal structure of the welding gun and extending its service life.

Forced groove vertical device: The scale tube of the new welding gun has added a forced groove vertical device to ensure that the laser is always in the center of the welding gun, improving welding accuracy and stability.

Fiberglass gasket: The new welding gun has added a fiberglass gasket, which can block 60% of the heat conduction backwards, effectively protecting the optical components at the back of the welding gun, extending its service life, and reducing consumable costs.

Eccentric design protective lens: The new welding gun's protective lens has a diameter of 3 centimeters and adopts an eccentric design to emit light from the side. It can be reused 6-8 times, greatly reducing the cost of consumables compared to traditional protective lenses.

Segmented design of gun body: The new welding gun adopts a segmented design, with the front half made of aluminum alloy and the rear half made of EPS material. This design not only provides better heat dissipation, but also effectively protects the rear collimating and focusing mirrors, further reducing consumable costs.

In the corner of the company, a certification wall silently declares Kempson's strength: ISO9001, CE, FDA... The quality director picked up a bottle of antifreeze and said, "During the three-year warranty period, we provide free direct mail to customers outside the province. Our self-produced gas laser welding technology can save customers 30000 to 40000 yuan in gas costs every year. Realistically, we even calculate the cost of antifreeze for customers

【 Conclusion 】

When leaving the laboratory, a smooth 12mm weld seam on the steel plate shone coldly under the light. Kempson's answer is clear: there is no shortcut to technological advancement, only innovation can penetrate every millimeter of barrier.

Previous page:

Next page: