What is Air handheld laser welding

2024-10-30

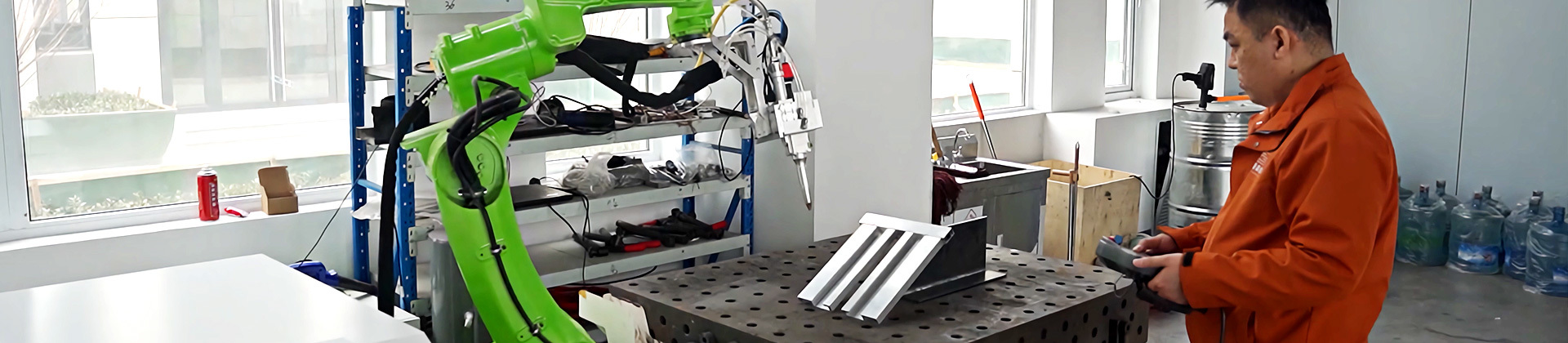

Handheld laser welding technology has revolutionized the welding industry by providing a more portable and efficient solution for joining metal components. With the advancement of air handheld laser welding technology, this process has become even more versatile and precise.

Air handheld laser welding utilizes a laser beam to heat and melt the metal components, creating a strong and durable weld. The use of air as a shielding gas in the welding process helps to protect the weld pool from oxidation and contamination, resulting in a cleaner and more reliable weld.

One of the key advantages of air handheld laser welding is its portability. Unlike traditional welding methods that require large and bulky equipment, handheld laser welding devices are compact and easy to maneuver. This allows welders to access hard-to-reach areas and perform welding tasks in tight spaces, making it ideal for a variety of applications in industries such as automotive, aerospace, and electronics.

In addition to its portability, air handheld laser welding offers exceptional precision and control. The focused laser beam allows for pinpoint accuracy, ensuring that the weld is placed exactly where it is needed. This level of precision results in high-quality welds with minimal distortion and heat-affected zones, making it suitable for welding thin and delicate materials.

Furthermore, air handheld laser welding is a fast and efficient process. The high energy density of the laser beam allows for rapid heating and cooling of the metal, resulting in quick welding speeds and reduced production time. This not only increases productivity but also reduces overall costs associated with welding operations.

Overall, air handheld laser welding is a versatile and reliable technology that offers numerous benefits for a wide range of welding applications. Its portability, precision, and efficiency make it an attractive option for manufacturers looking to improve their welding processes and achieve high-quality welds. As this technology continues to evolve, it is expected to play an increasingly important role in the future of the welding industry.

Previous page:

Next page:

Contact Us

Address: Building 26, U Valley, Hongqi District, Xinxiang City, Henan Province, China

Become A DistributorCOOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.